Ferrari Maserati of Long Island

Plainview, NY | Oct 2024

For over seven decades, Ferrari has embodied a legacy of excellence, seamlessly blending tradition with cutting-edge innovation to deliver unmatched performance in the automotive world. This enduring commitment to precision and progress set the tone for the construction of its premier dealership in Long Island.

To ensure the structure met the highest standards of durability and design, especially in the critical area of roof waterproofing, developers turned to a company with an even longer history and a shared dedication toward innovation, performance, and enduring quality.

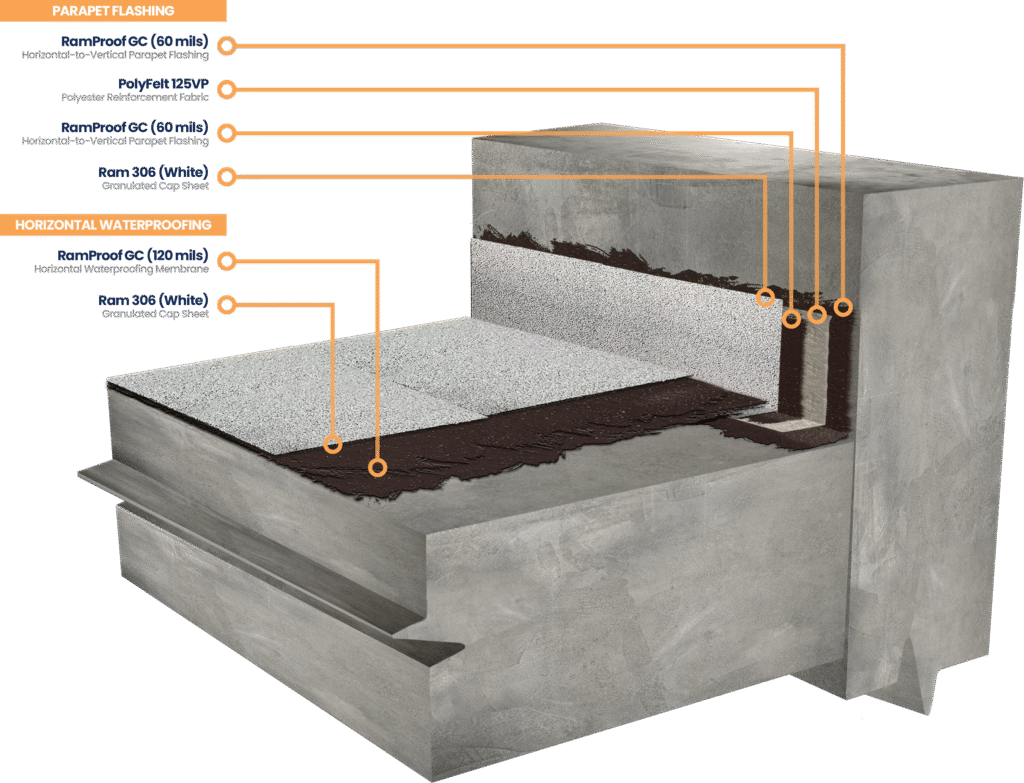

For the utmost performance and protection, Barrett recommended contractors utilize 120 mils of RamProof GC (Green Concrete) single-component, fluid-applied elastomeric rubberized asphalt roofing and waterproofing material for this 15,000 sq/ft application.

Topped with a Ram 306W white granular cap sheet, the resulting asphaltic-rubber membrane provides a fully adhered monolithic waterproofing system that is VOC-free, environmentally friendly, and LEED certified. And like that of a Ferrari, it guarantees performance, speed, and quality.

Parapets were coated with 60 mils of RamProof GC reinforced with PolyFelt 125VP polyester reinforcement fabric, followed by a second 60-mil coat of RamProof GC. Similarly, all drains were coated with 60 mils of RamProof GC reinforced with RamFlash 327 HDR uncured neoprene flashing, followed by a second 60-mil coat of RamProof GC overtop the neoprene.

Once fully adhered, the Ram 306 is covered with RamDrain DD-025 prefabricated dimpled drainage board, followed by a layer of insulation and a concrete slab. This assembly comes with a complete 20-Year Single-Source Warranty.

A national leader in the roofing and waterproofing industry since 1928, The Barrett Company has provided customers with hands-on experience and professionally engineered products. As with many before, Barrett’s advanced roofing and waterproofing systems proved integral to delivering a high-performance solution worthy of the Ferrari name.

NOTES FROM CRAIG:

- Reinforced all transitions 8” inches up the vertical and 8” on the horizontal (minimum reinforcing height is 3” up and 3” out).

- CONCRETE was poured over Ram 306 after application.

- Applicator wanted to bring the material up higher ending just below the final elevation once topping slab was poured (horizontal to vertical up the Parapet walls) 60 mils RPGC then embedded the Polyfelt 125 VP and applied an additional 60 mils of RPGC

- RamProof GC (120 mils)

- Ram 306 W

- Ram DD025 Dimpled Drainage Layer

- Insulation

- Topping Slab over Insulation

- Drains were reinforced with HDR 327 Uncured neoprene set in 60 mils of Ram Proof and applied another 60 mils on top of the neoprene.

- 2 ft x 2 ft piece of neoprene tape

- Set it over the drain

- Star cut and push

- Field work was 120 mils of Ram Proof GC unreinforced with our 306 White Granulated Cap Sheet.

- 20-year warranty