“Restore & Repair So You Don’t Have to Replace”

After evaluating the roof of their 240,000 sq/ft facilities building, the management team at LinkBelt Construction Equipment did just that.

Thanks to Barrett’s Ram Cold Tar® Plus roof restoration & repair system & Ram Ultra-Silver® reflective aluminum finish, the result was a new, fully detailed, watertight roofing system that saved the company time, money, and energy.

OVERVIEW

Link-Belt, a leading manufacturer of giant hydraulic and lattice cranes, evaluated their 14-year-old, 260,000 sq/ft bituminous roof as part of their on-going preventative maintenance program. Originally installed by the Bri-Den Company, the roof was found to be in reasonably good condition but showing normal signs of wear and tear.

After reviewing various roofing options, Link-Belt decided to invest in a Barrett’s Ram Cold Tar® Plus roof restoration & repair system, including a highly reflective Ram Ultra-Silver® Energy Star®-rated aluminum finish.

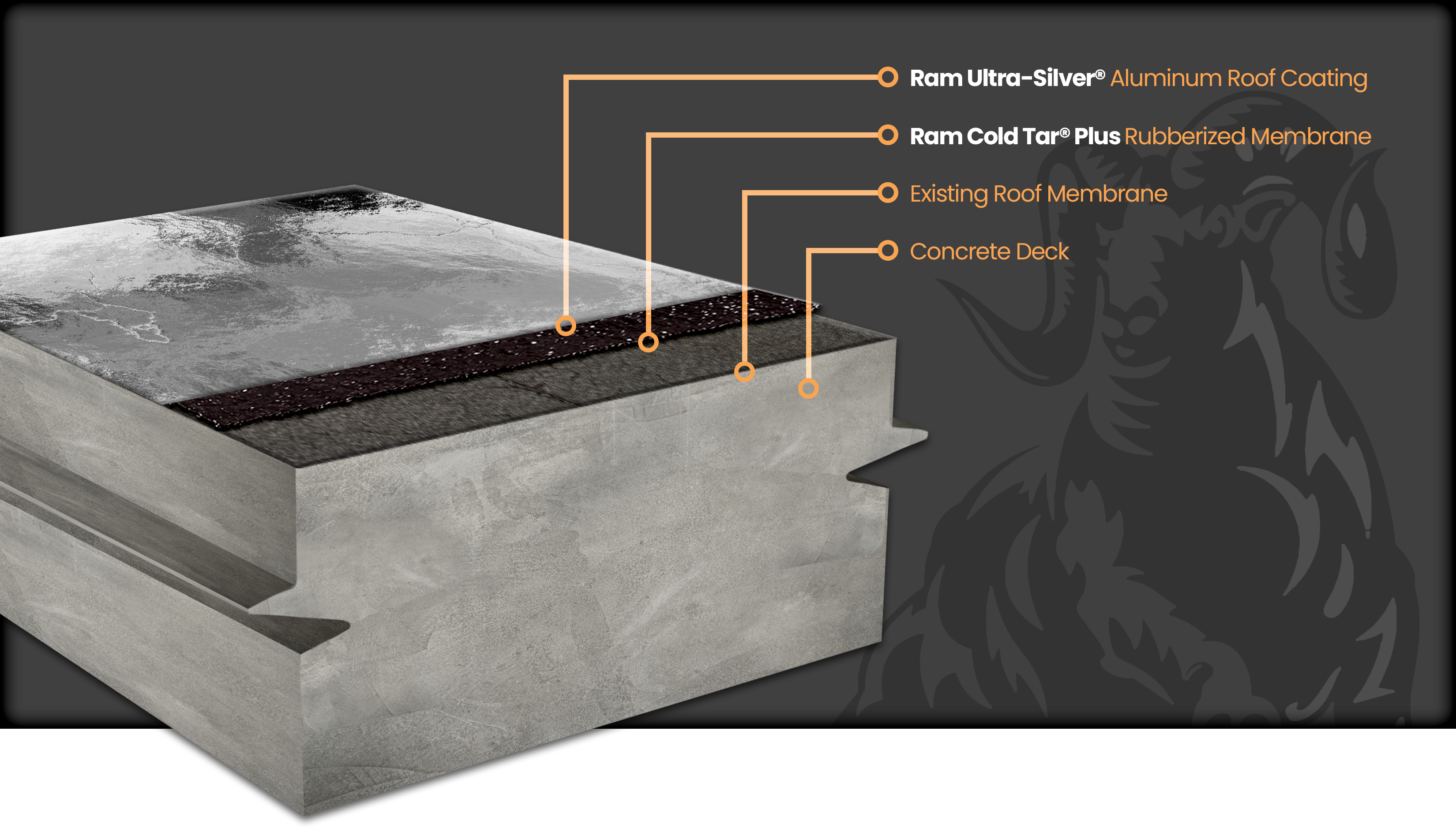

SYSTEM COMPONENTS

Using the existing bituminous roof mat as a substrate, Barrett’s Ram Cold Tar® Plus fuses a new, high-strength, fluid-applied rubbery membrane to the mass of the old roof mat, creating a new, double thick, elastomeric waterproof membrane. A surface coat of Ram Cold Tar® Plus not only offers a superior flexible weathering surface, but the resistance to ponding water, a well-known characteristic of coal tar. And the highly reflective aluminum surfacing reduces membrane and interior temperatures.

The Bri-Den Company was again selected to do the work and began by performing a detailed survey of the roof with a Barrett representative. The restoration started with minor repairs to the membrane and flashings. After the preparation work was complete, the Ram Cold Tar® Plus fluid membrane was applied and allowed to cure before applying the aluminum surfacing.

PICTURED: Application of Ram Ultra-Silver® aluminum surface coating over the cured Ram Cold Tar® Plus membrane. The restoration started with minor repairs to the membrane and flashings. After the preparation work was complete, the Ram Cold Tar® Plus fluid membrane was applied and allowed to cure before applying the aluminum surfacing.

An efficient and economical alternative to re-roofing, Barrett’s Ram Cold Tar® Plus can save 40-60% of full roof replacement costs by extending the service life of an existing bituminous roof for years, reducing both the life cycle cost of the original roof and the energy usage of the building as a whole.

While classified as a “repair,” the result is a new, fully detailed, watertight roofing system that is guaranteed to perform.

Not all roofs are suitable for restoration but when appropriate, restoration is an extremely cost-effective solution that limits inconvenience to the building occupants, saves existing insulation, and reduces tons of waste from going into landfills. Generally, roof restorations can be expensed in the same year, avoiding an expensive 39-year IRS depreciation schedule.

The Bri-Den Company, with offices in Lexington, KY (859-255-1885) and Ashland, KY (606-325-8639) has been serving the needs of commercial and industrial roofing and sheet metal customers since 1986.

To learn more about the benefits of a Ram Cold Tar® Plus Roof Restoration or have a Barrett Representative survey your roof, contact the Barrett Company at (800) 647-0100