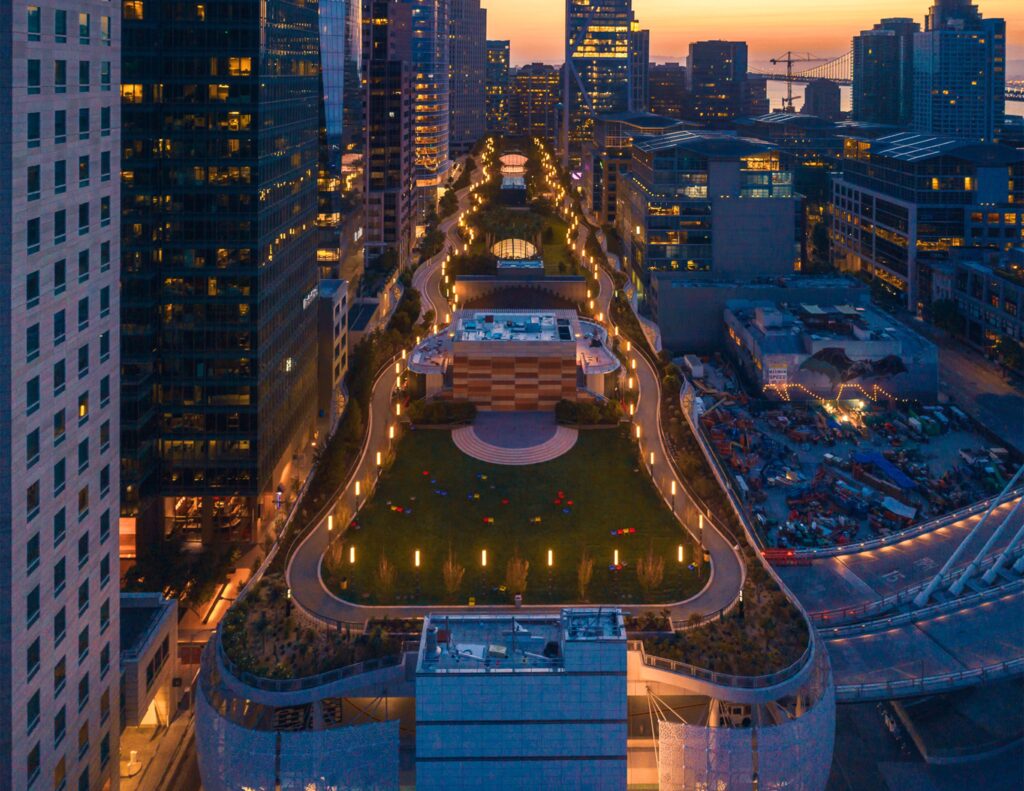

Salesforce Transit Center is a landmark for the San Francisco Bay Area. This striking, innovative, and sustainable multi-story building transforms a transportation hub into an urban experience, complete with a gondola, and topped off by a 5.4-acre rooftop park open to the sky.

A GRAND SPACE FOR THE SAN FRANCISCO BAY AREA

Behind the curvature of a pearlescent lace-like awning, this multi-story San Francisco landmark transforms a commuter hub into an urban destination. With interiors open to the light, it’s a sociable, open space for people to gather, topped by a leafy park where the sky is the roof.

The Salesforce Transit Center is a green infrastructure that enhances public transportation, reduces traffic congestion, and serves as an economic catalyst. As San Francisco’s new downtown gateway, it greets tens of thousands of residents, commuters, and visitors daily, providing a dynamic destination while engaging, enriching, and connecting people coming and going throughout the San Francisco Bay Area.

Salesforce Transit Center will fundamentally change the way people connect between Northern and Southern California via public transportation, including high speed rail, in and out of the San Francisco Bay Area from the world’s most open, green, and dynamic setting.

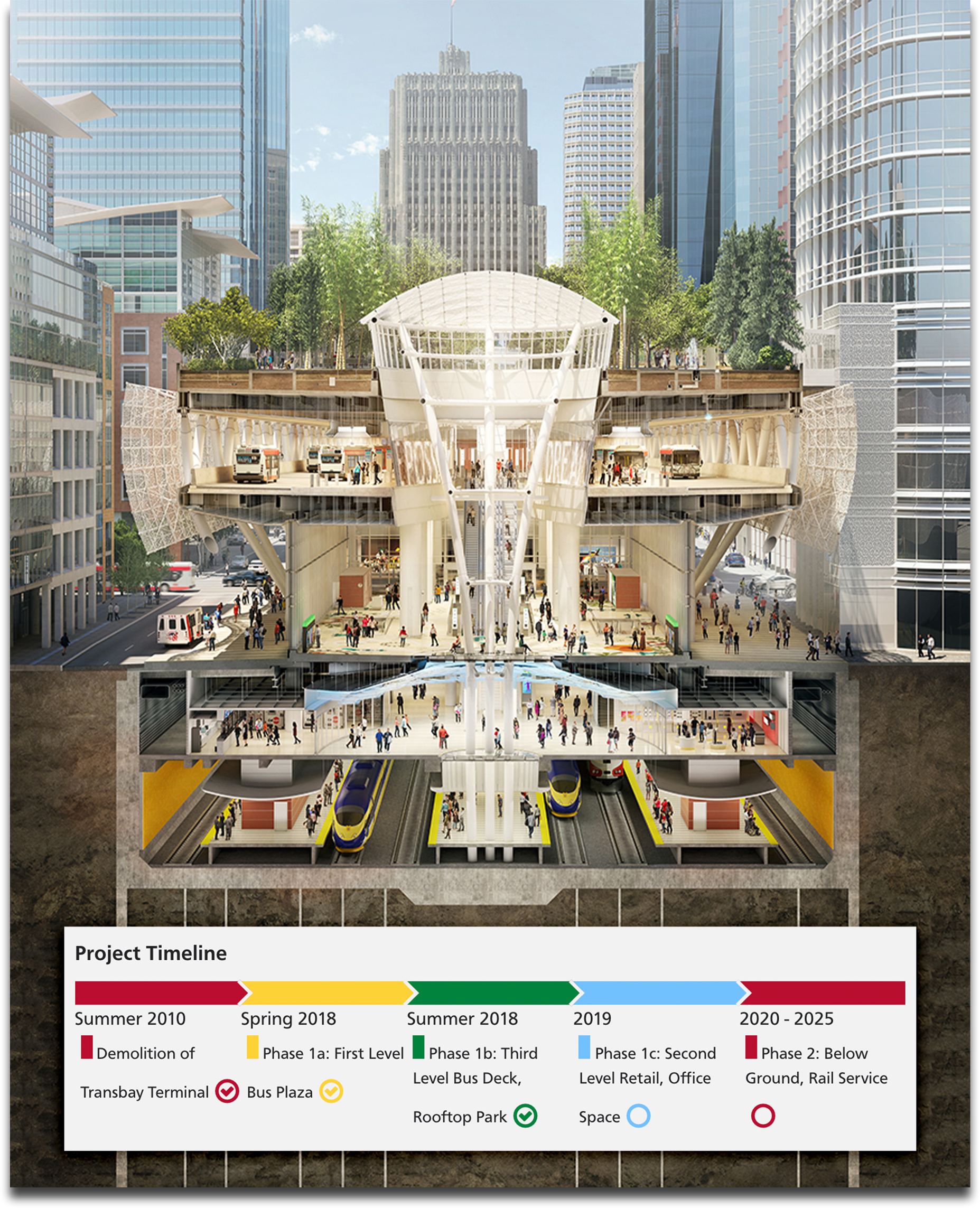

CONSTRUCTING IN PHASES

The Salesforce Transit Center project, which began in 2010, is set to become the “Grand Central Station” of the west, a fully integrated transit hub capable of getting people to any major destination in the region from one central location using only public transportation.

The major project elements include:

• Two-block-long bus deck with direct freeway access for AC Transit, WestCAT, Amtrak Thruway and Greyhound buses and Muni service to Treasure Island (25)

• A ground level bus plaza serving six major Muni lines (5/5R, 7 and 38/38R)

• A three-platform, 6-track train station underground

• A Grand Hall entrance lobby and a rooftop park

To achieve such a feat for the massive regional transit hub, which sits just south of Mission Street between Second and Beale streets in downtown San Francisco, the project has been broken into four major phases of construction.

Phase One of the project connects the bus services of AC Transit, WestCAT, Greyhound and Amtrak Thruway bus service with Muni service in San Francisco. Phase Two of the project will bring in Caltrain train service from the peninsula and eventually California High Speed Rail trains from Southern California into an underground station. The multi-level building (four stories above grade and two below) includes a rooftop public park, retail space, bicycle parking and administrative offices.

A TRANSIT CENTER BUILT TO LAST

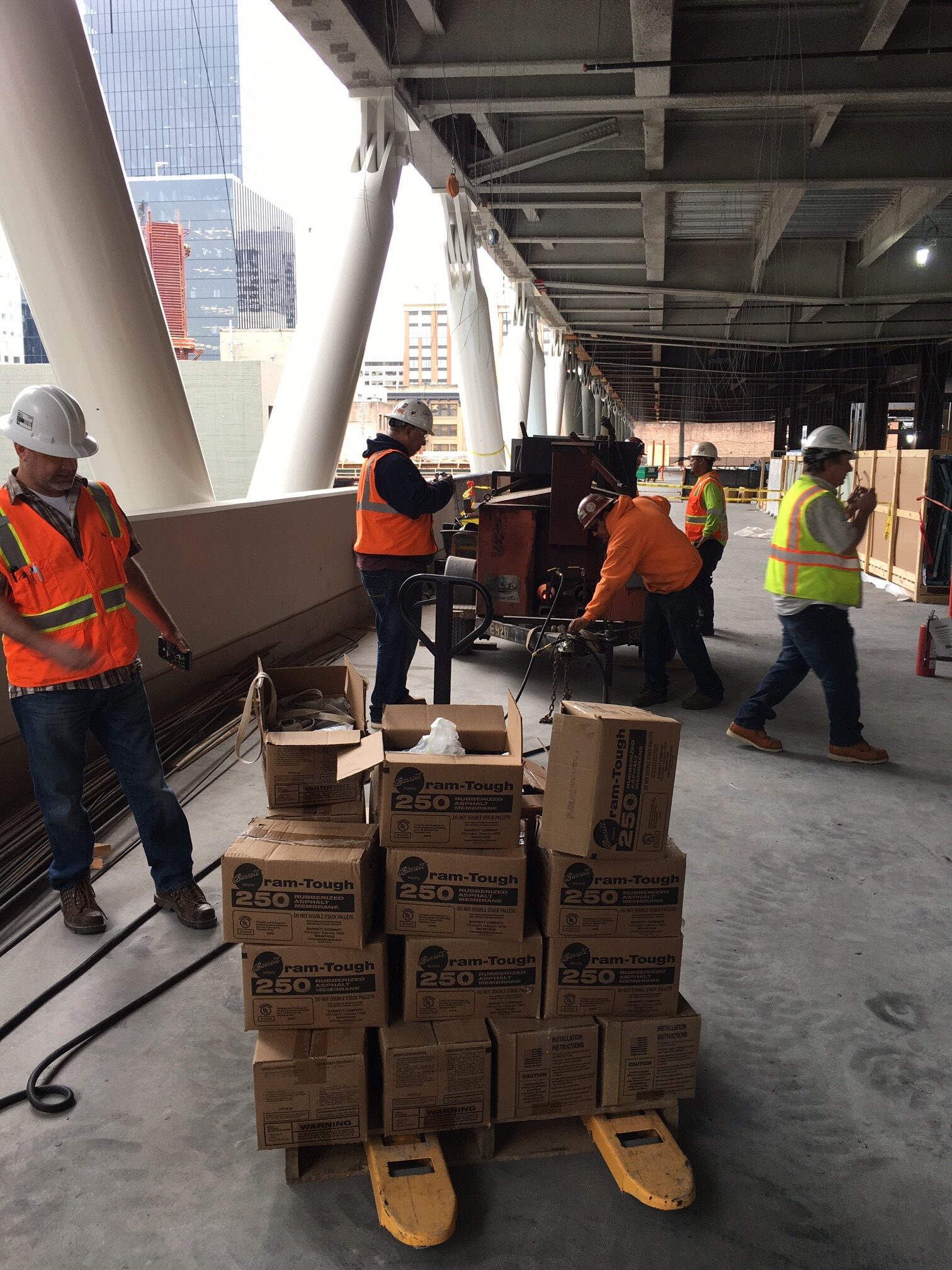

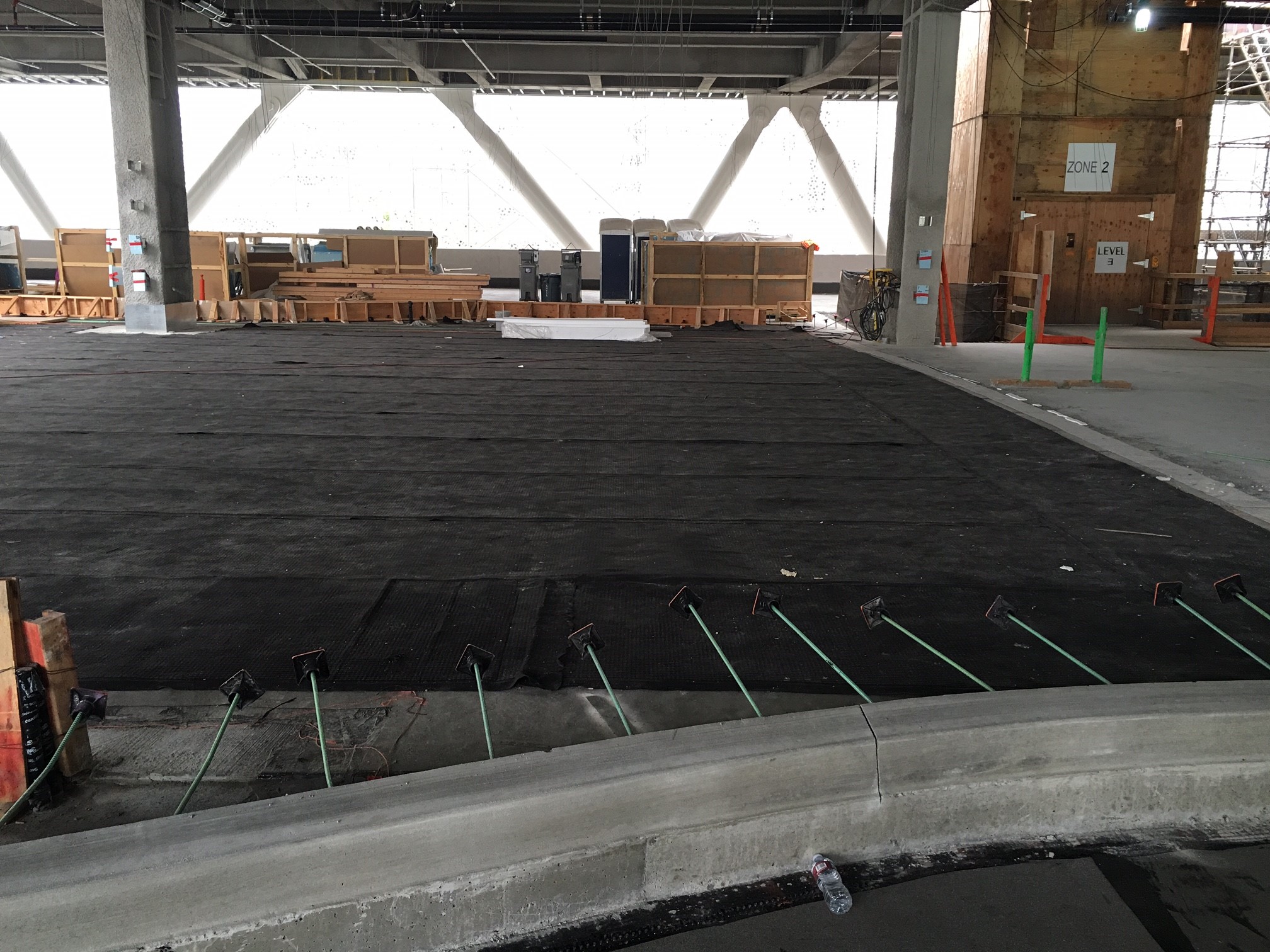

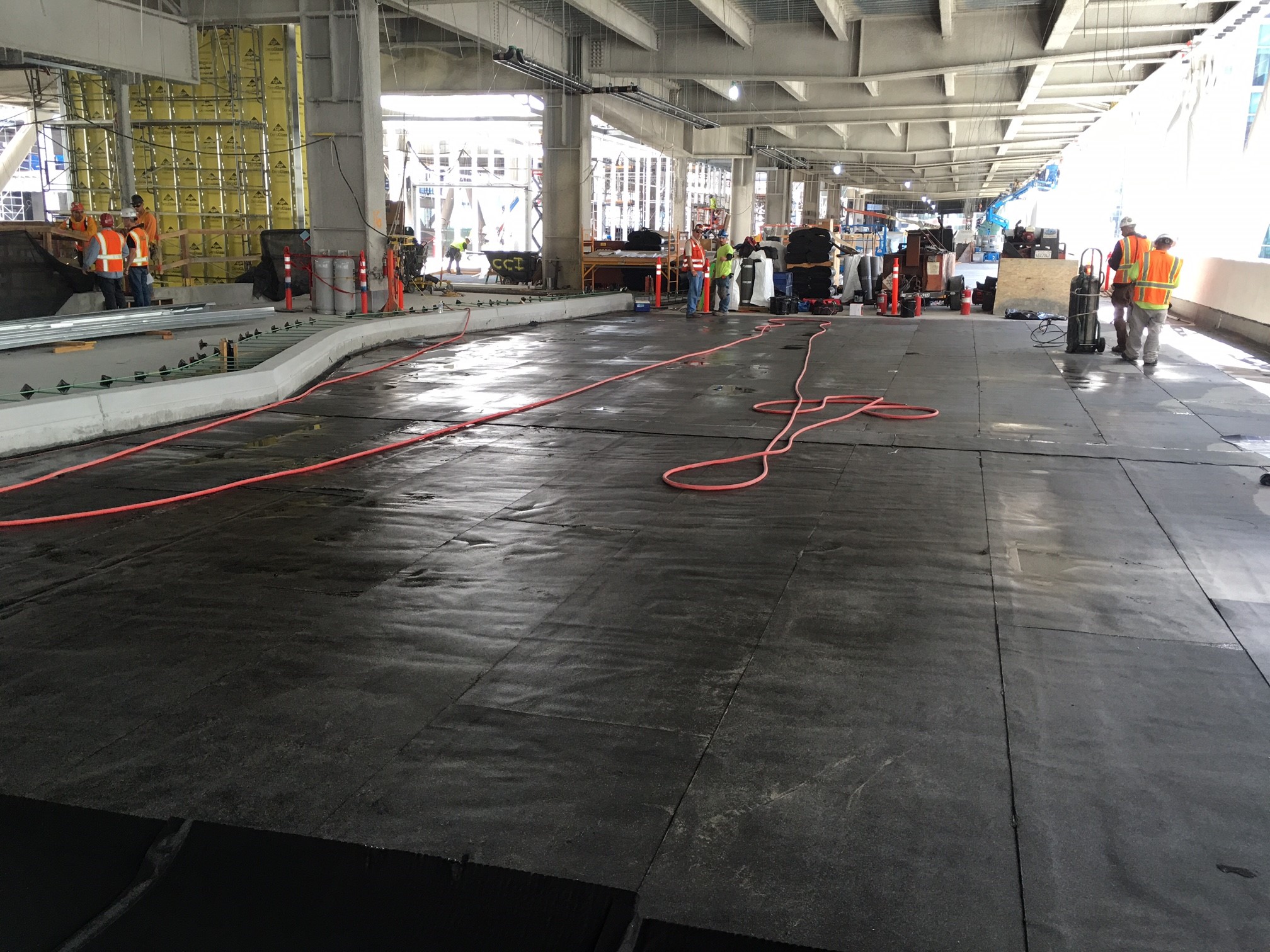

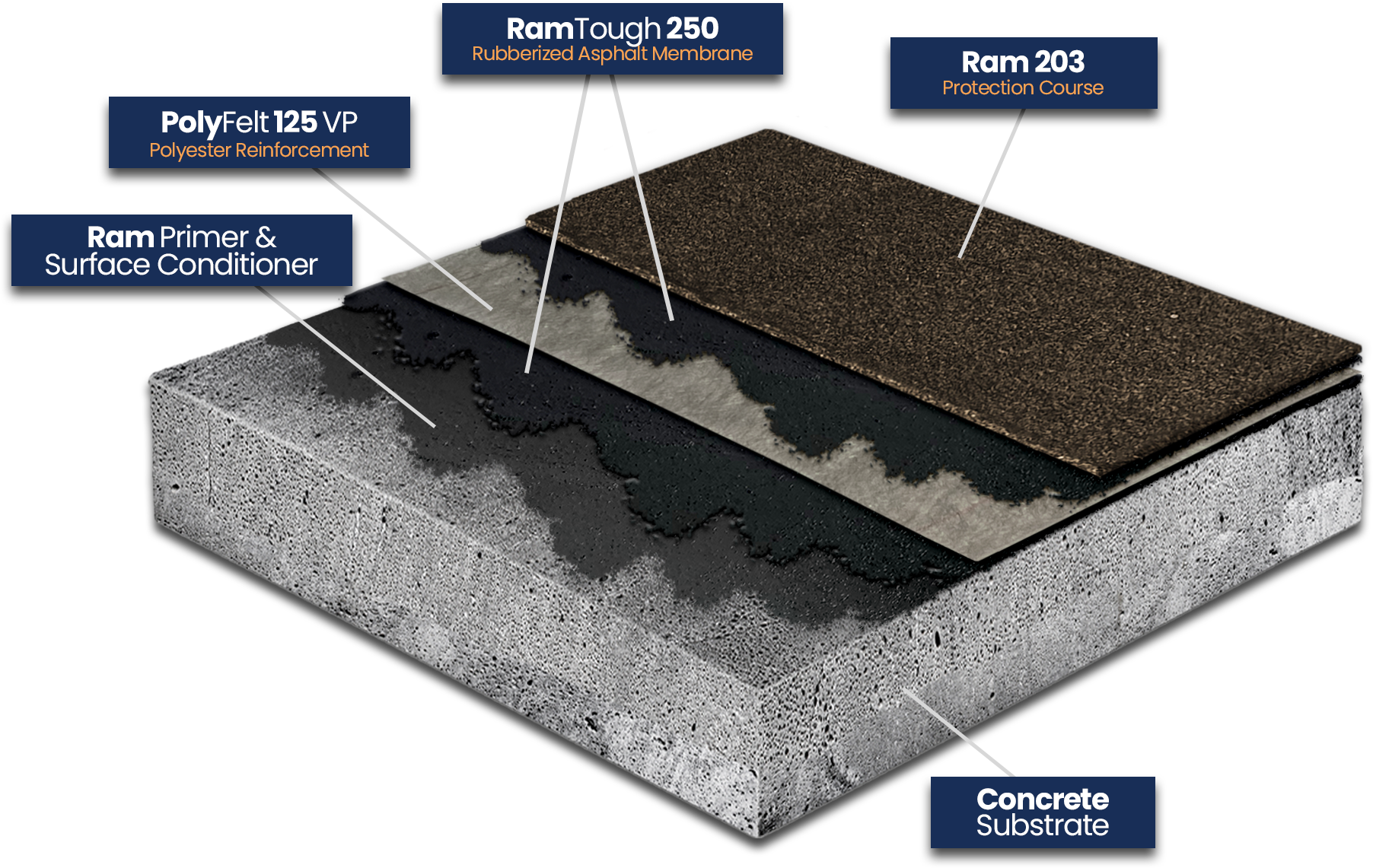

For a municipal terminal that would handle extensive vehicular and pedestrian traffic on a daily basis, there needed to be a waterproofing system capable of providing both durability and lasting protection. Naturally, Barrett’s RamTough 250 Hot Rubberized Asphalt was chosen for the two-block long bus deck.

The core of Barrett’s RamTough 250 waterproofing systems is a fluid-applied rubberized asphalt membrane, which forms a completely monolithic waterproof barrier without seams or joints. The RamTough 250 formulation and manufacturing process yields a self-healing, elastomeric material with significantly better elongation, elasticity, low temperature flexibility, adhesion and toughness properties compared to all other types of membranes.

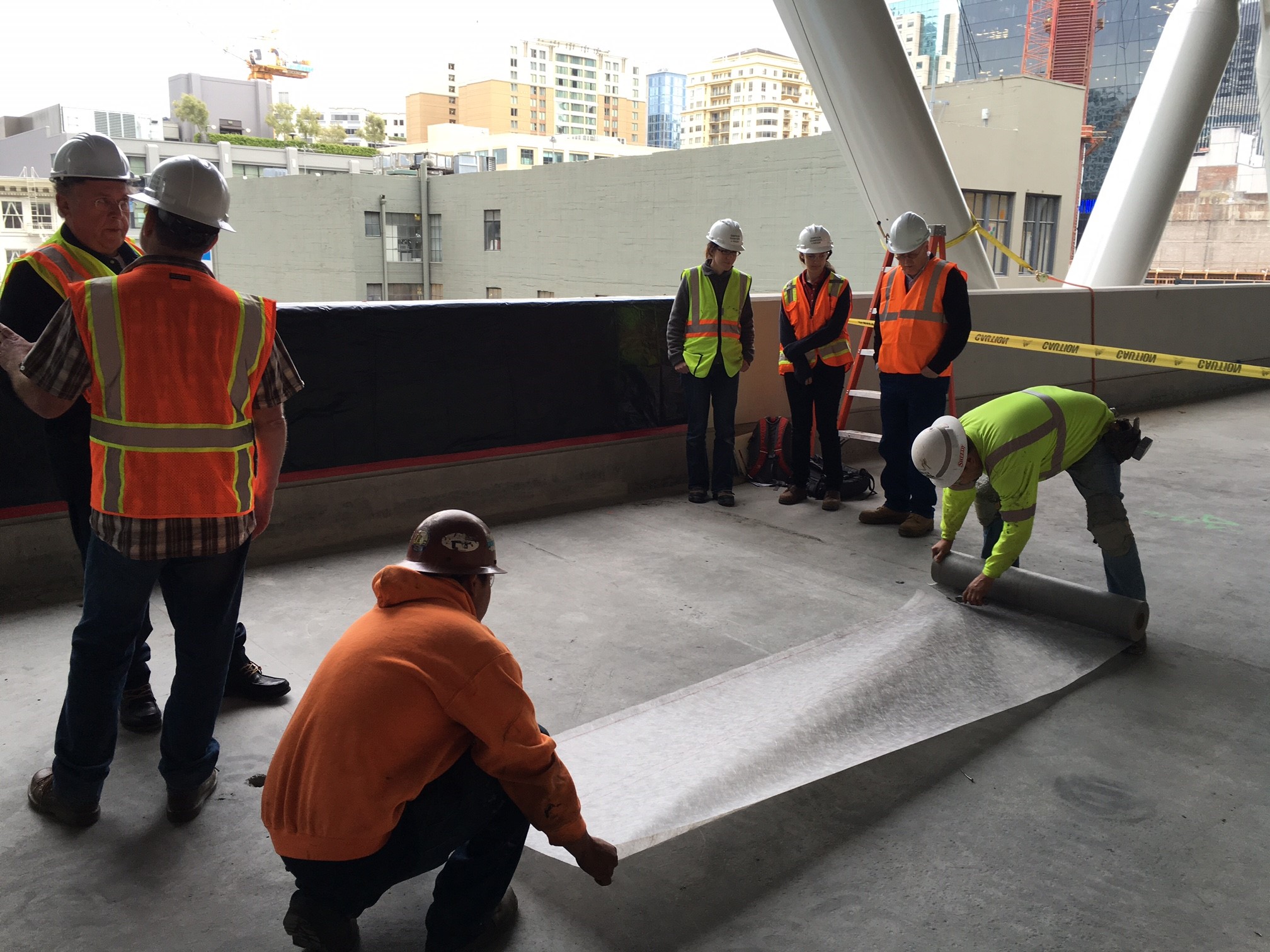

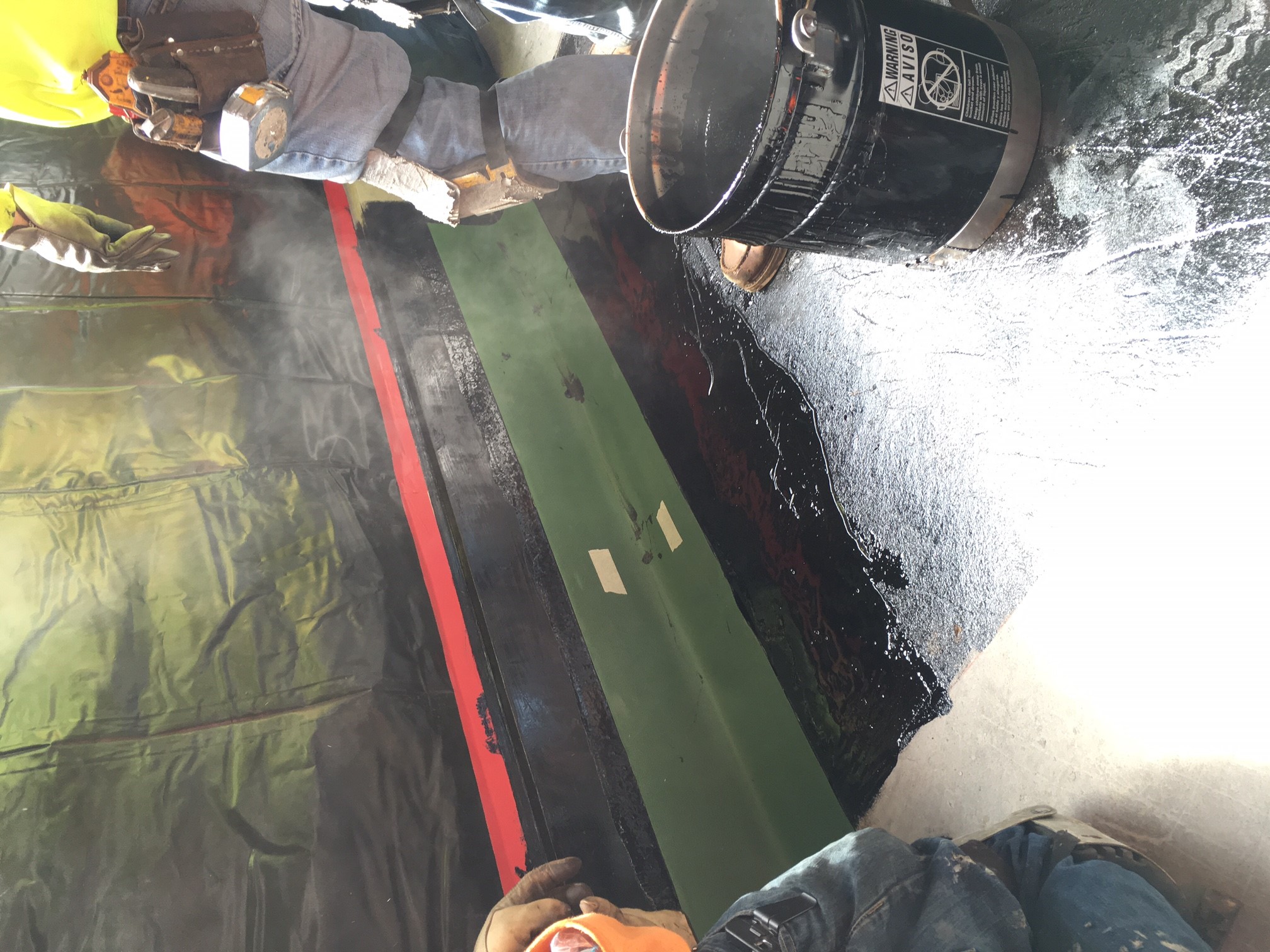

RamTough 250 waterproofing is composed of SBS rubber polymers, specially refined unoxidized asphalt, recycled tires and mineral filler. It is melted on the jobsite, spread on the deck 90 mils thick over a coat of Ram Primer & Surface Conditioner, reinforced with PolyFelt 125VP polyester fabric, overcoated with another 125 mils of RamTough 250 and covered with Ram 203 SBS reinforced protection course, creating a total membrane thickness of approximately 300 mils. Totally adhered, water cannot get under or through this four course application. With the protection layer in place, the membrane is ready to accept a variety of traffic bearing surfaces, insulation, aggregate ballast or a green roof assembly.

The unique physical properties of the RamTough 250 system offer superior performance and durability, even in the presence of ponded water and extreme climate variations. RamTough 250 is easy to install, seals difficult flashing conditions, and remains flexible for its lifetime.

DUTIFULLY DETAILING DIAGONAL TERMINAL TERMINATIONS

For this particular project, there seemed to be a variety of fairly complex design considerations to factor in before the installation process could begin. Luckily, Bill Gillette from Building Envelope Technology Associates, LLC was there to work with the contractors from Best Contracting Services in order to ensure proper application methods and best practices.

AN AMERICAN-MADE TRANSIT CENTER

However, its history of lasting performance as a waterproofing membrane was not the only driving factor behind the selection of Barrett’s RamTough 250 Hot Rubberized Asphalt. As it turns out, The Salesforce Transit Center project fell under the Federal Transportation Administration’s “Buy America Act”.

FTA’s Buy America requirements prevent FTA from obligating an amount that may be appropriated to carry out its program for a project unless “the steel, iron, and manufactured goods used in the project are produced in the United States.” FTA’s Buy America requirements apply to third-party procurements by FTA grant recipients. A grantee must include in its bid or request for proposal (RFP) specification for procurement of steel, iron or manufactured goods (including rolling stock) an appropriate notice of the Buy America provision and require, as a condition of responsiveness, that the bidder or offeror submit with the bid or offer a completed Buy America certificate in accordance with 49 CFR §§661.6 or 661.12.

Unlike rolling stock, manufactured goods must be 100-percent produced in the U.S. A manufactured good is considered produced in the United States if:

• All of the manufacturing processes for the product take place in the United States

• All of the components of the product are of U.S. origin. A component is considered of U.S. origin if it is manufactured in the United States, regardless of the origin of its subcomponents. (49 CFR 661.5(d).

FTA has issued a number of Buy America guidance letters discussing manufactured goods. Because all of our materials are manufactured in the United States, Barrett’s RamTough 250 was fully qualified for the project.

Click through the gallery below to see images from the application process.

(Photos courtesy of Bill Gillette)