The Foreman’s Guide: Horizontal Waterproofing with RamTough 250

The core of Barrett’s RamTough 250 waterproofing systems is a fluid-applied rubberized asphalt membrane, which forms a completely monolithic waterproof barrier without seams or joints.

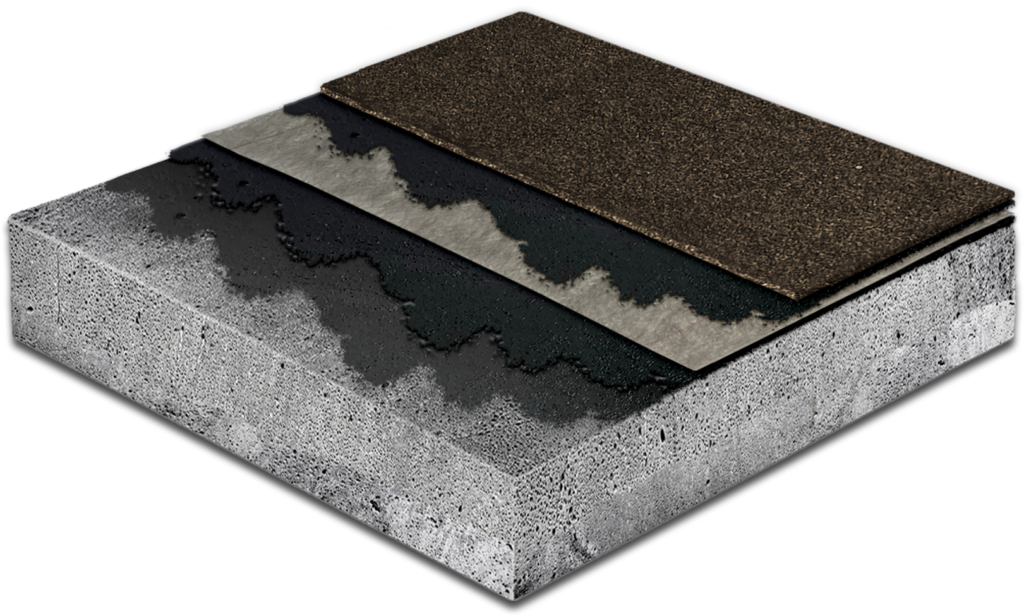

APPLICATION LAYERS

- Ram 203 | Protection Course (1 Ply)

- PolyFelt 125 VP | Reinforcement Fabric (1 Ply)

- RamTough 250 | Rubberized Asphalt (1st Coat)

- Concrete Substrate

The RamTough 250 formulation and manufacturing process yields a self-healing, elastomeric material with significantly better elongation, elasticity, low temperature flexibility, adhesion and toughness properties compared to all other types of membranes.

RamTough 250 waterproofing is composed of SBS rubber polymers, specially refined unoxidized asphalt, recycled tires and mineral filler. It is melted on the jobsite, spread on the deck 90 mils thick, reinforced with polyester fabric, over-coated with another 125 mils of RamTough 250 and covered with an SBS reinforced protection course, creating a total membrane thickness of approximately 300 mils. Totally adhered, water cannot get under or through this four course application. With the protection layer in place, the membrane is ready to accept a variety of traffic bearing surfaces, insulation, aggregate ballast or a green roof assembly.

The unique physical properties of the RamTough 250 DM system offers superior performance and durability, even in the presence of ponded water and extreme climate variations.

SLOPE & DECKS

Decks up to 1 in/ft incline require no special precautions. Contact Barrett Technical Services for slopes over 1 in/ft, vertical applications and decks other than concrete.

SURFACE PREPARATION

Concrete decks must be made reasonable smooth, dry, free of dirt, laitance, curing agents, debris and other contaminants. Prior to installing the membrane, apply a coat of Ram Primer and Surface Conditioner at a rate of 300-500 sq.ft./gal to all surfaces to be waterproofed. Allow the coat to dry thoroughly. Before proceeding, treat all cracks, construction and expansion joints in accordance with Barrett recommendations or approved details.

MEMBRANE APPLICATION

Starting at the low points of the deck, apply a base coat of RamTough 250 no less than 90 mils thick and approximately 44” wide. While still hot, install one ply of PolyFelt 125 VP reinforcement fabric into the RamTough 250. Standing off to the side, use a broom or squeegee to press the fabric into the hot bitumen carefully, so as to not create wrinkles or fish-mouths. If the sheet is not set straight and begins to run off a straight line, cut the roll and reset it, overlapping the end of the sheet by 12”.

After the first run has been installed, return to the same starting point and install a second run of RamTough 250 and reinforcement, overlapping the first course by 3”. All end laps shall be a minimum of 6”. Ensure that there is a solid coat of RamTough 250 between all laps. There should be no place where fabric touches fabric. All laps shall be laid to allow for the flow of water over the lap, not against it. Continue working up the slope.

After the base coat of waterproofing and reinforcement have been completed, apply a top coat of RamTough 250, applied at a minimum thickness of 125 mils.

WATER TESTING

It is recommended that all sections of the completed membrane installation be flood tested in accordance with ASTM D-5957 for 48 hours. Any leaks shall be repaired and the area retested. Some applications may require an Electronic Field Vector Mapping Test (EFVM) conducted by an approved surveyor.

PROTECTION COURSE

Once the water test is complete, install 1 ply of Ram 203 protection course. Provide 2” side-laps and 6” end-laps. The protection course is to cover all horizontal surfaces, as well as all vertical flashings. If the base flashing is to be permanently exposed, install 1 ply of Ram 306 granulated cap sheet into the top coat of RamTough 250 in lieu of the Ram 203. Use RamTough 250 as an adhesive, as required, to hold the protection course in place prior to it being covered with the specified surfacing.

SURFACING

Carefully install surfacing overburden (e.g. insulation, filter fabric and ballast, pavers, green roof assembly. etc.) as per the project specifications.

PRODUCT SAFETY INFORMATION

RamTough waterproofing products offer no unusual health or safety risks for products of this nature. As with any roofing and waterproofing installation process, proper ventilation, clothing and eye protection is important.

For specific product information, contact the Barrett Company for a current Material Safety Data Sheets for any and all Barrett products. Obtain Material Safety Data Sheets from manufacturers whose materials may be used in conjunction with the Barrett waterproofing system. For installation safety information, consult the National Roofing Contractors Association (NRCA), the Occupational Safety and Health Administration (OSHA), and any other informed sources.

The user should not assume that all safety measures are indicated or that other measures may not be required.

NOTE: All product literature (i.e. technical & safety data sheets, specifications, application instructions, etc.) is currently available to download from the “Resource Library” on our website.

For questions regarding detailed specifications, application information, or any other general inquiries, please reach out to your local Barrett Technical Representative.

You can also call us directly at (800) 647-0100 or email us at info@barrettroofs.com