The Foreman’s Guide: Cold Weather Applications for Roofing, Waterproofing, and Restoration Systems

Application of a roofing, waterproofing or restoration system in cold weather can be achieved successfully, within certain limitations, if precautions are taken.

It is important to understand what may be encountered during cold weather applications and what material and manpower limitations exist. Following these cold weather suggestions will help provide greater application efficiency and system performance.

Acceptable weather conditions are based not only on the actual ambient temperature, but a total combination of elements (e.g., wind, humidity, frost, dew and precipitation). The “wind chill” factor will have a great deal of influence not only on materials, but also on workmanship. Careful planning of work during cold weather will improve the quality of the installation. Laying out the roof area and placing materials where they will be needed prior to application will lessen problems associated with cold weather application.

Where different grades of materials are specified for summer or winter use, the grade specified for cold weather should be used.

Polymer Modified Elastomeric Roofing Bitumen

Applying RamTough KLB-100 Polymer-Modified Elastomeric Roofing Bitumen

At the point of application of the roofing plies, the mopping asphalt should be at the recommended temperature. Failure to keep the asphalt in the proper application temperature range will result in poor ply adhesion, slippage and over usage of material.

The maximum heating temperature in the summer should be 500°F and in the winter, 525°F. The EVT of 125 cP (centipoise) with KLB-100 is generally around 500°F. However, the ideal viscosity of SEBS modified asphalt is approximately 180 cP, which occurs at about 450°F.

To compensate for the rapid cooling of mopping asphalt in cold weather, it is extremely important to keep the asphalt within the specified range, but never less than 400°F and not greater than 525°F at the kettle.

SEBS modified bitumen material is heat sensitive and should not be held at elevated temperatures for prolonged periods of time. If bitumen usage throughout the day is expected to be of limited quantity, consider using a smaller kettle or keeping a smaller volume of material in the kettle to avoid prolonged heating of the bitumen that could occur in a large kettle or tanker.

Felts must be installed into the hot mopping as rapidly as possible to guarantee adequate embedment. Mopping should not precede the roofing plies by more than five feet to prevent premature cooling of the bitumen. Brooming the felts in place immediately is very important.

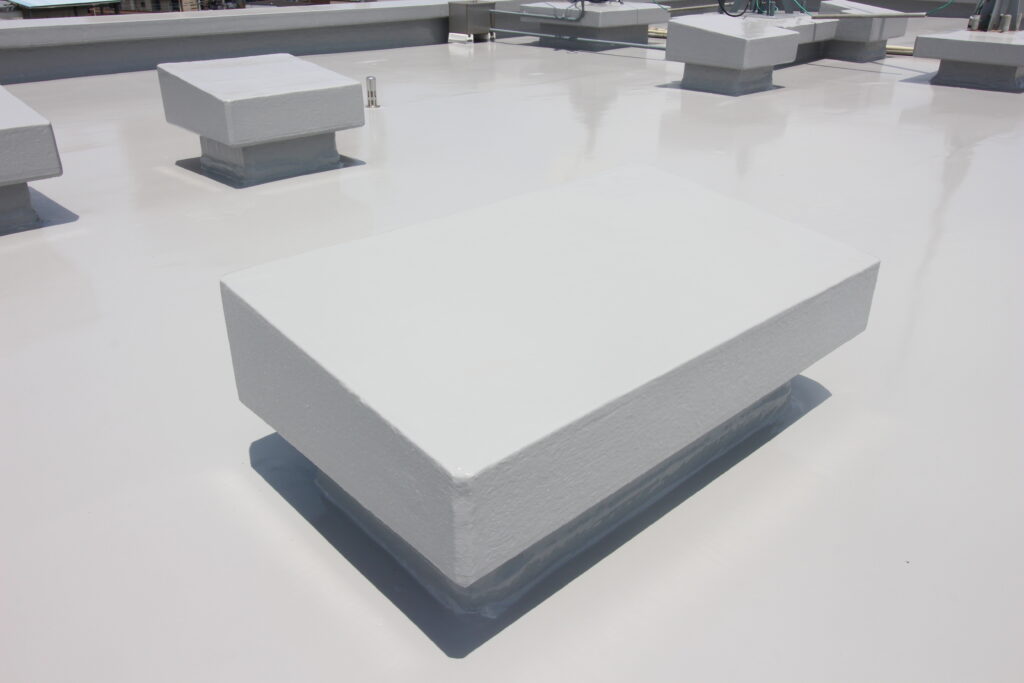

Proper insulation of all asphalt handling equipment is required to keep bitumen at an appropriate application temperature in cold weather. The use of insulated rooftop equipment for transporting asphalt across the roof, such as hot luggers and mop buckets, is recommended.

This is especially important when bitumen is being transported over long distances on the roof. Bitumen pumping lines from the kettle to the roof should also be insulated, as they tend to clog in colder temperatures.

Ultimately, Barrett does not recommend installing built-up roofing applications below 25°F under any circumstance.

Roof Membrane Application Precautions

Asphaltic base sheets, plies and cap sheets become less flexible in cold temperatures. Rolls should be stored on end and when possible, in a warm (>50°F) and dry location prior to application. As the work progresses on a day-to-day basis, it is essential that each section of the roof be completed as specified. “Phased construction is not acceptable”.

Hot Rubberized Asphalt Waterproofing System

Applying RamTough 250 Hot Rubberized Asphalt Waterproofing Bitumen

RamTough 250 bitumen can be installed at 0°F. However, the installation techniques become critical. Use approved double-jacketed melters with mechanical agitation. Begin melter warm-up early enough to have hot fluid material when the work is scheduled to start. Cold weather start-up will take longer.

Regulate melter to maintain material temperature range of 375°F to 400°F, with constant agitation. Do not overheat RamTough 250. To compensate for the rapid cooling in cold weather, it is extremely important to keep the Ram-Tough 250 within its specified range, never less than 350°F and never greater than 425°F. It is important not to hold RamTough 250 material at elevated temperatures for prolonged periods of time. Generally, the upper limit recommendation is four (4) hours at 400°F.

At the point of application, the RamTough 250 bitumen should ideally be 325°F-375°F. Failure to keep the RamTough 250 at the proper application temperature could result in excess material usage.

When applying a RamTough 250DM system, the reinforcing ply must be installed before the bitumen cools to assure adequate embedment. RamTough 250 should not precede the reinforcing ply by more than five feet to prevent premature cooling of the bitumen.

Proper insulation of all RamTough 250 handling equipment is required to keep bitumen at an appropriate application temperature in cold weather. The use of insulated rooftop equipment, such as hot luggers and buckets, is highly recommended for transporting the bitumen to the worksite. This is especially important when bitumen is being transported over long distances. Bitumen pumping lines from the melter to the work location are not recommended with RamTough 250, as they tend to clog in colder temperatures.

Cold Applied

Roofing, Waterproofing, & Restoration Systems

Pail materials, such as cements and coatings, should be properly stored with tight-fitting lids to prevent moisture intrusion or other forms of contamination. Use winter grade material and store in heated space if possible.

Applying Ram Ultra-White® and Other Water-Based Coatings

Water-based coatings must be stored in a warm (>35°F) location to prevent freezing. Should any material freeze, be sure to properly discard it.

It is recommended that these products be applied when temperatures are 40°F and rising and that temperatures will remain above freezing until the material has cured sufficiently. Depending on weather conditions, cure time can range from 24 to 48 hours or more.

Applying Solvent-Based Coatings

- Ram Cold Tar® Plus

- CP-80 Cold Process Adhesive

- Ram Ultra-Silver®

- Ram Primer Surface Conditioner

- Ram Mastic

Although not susceptible to freezing, these bituminous based coatings will become stiff and harder to apply at colder temperatures. It is recommended that the application temperature for these products be 40°F and rising.

Storing materials in heated storage until the time of application will make application easier and require less material. Care should be taken not to apply these materials heavier than recommended. Heavy applications will effect cure time and contribute to other performance problems.

HANDLING RECOMMENDATIONS

- Store all materials in a manner that assures they remain clean and dry prior to application. Temperature sensitive materials must be stored in heated spaces as required.

- When materials are stored outside, they should be placed on platforms that are raised off the ground or roof deck and be covered with breathable, water-resistant coverings, such as canvas, that are properly secured.

- Roll materials should be stored on end. Rolls with selvage edge should be stored with the selvage edge facing up to prevent damage. Double stacking of roll materials is not recommended.

- Moisture, dirt, snow, and ice must be removed from asphalt before it is heated.

- Insulation materials should be handled with care and stored in accordance with the manufacturer’s instructions. Perlite and wood-fiber insulation are particularly prone to atmospheric moisture pick-up and damage.

- If the hot bitumen begins to foam, bubble, or create a snapping/popping sound when applied to the substrate, immediately stop the application and check the material temperature.

NOTE: All product literature (i.e. technical & safety data sheets, specifications, application instructions, etc.) is currently available to download from the “Resource Library” on our website.

For questions regarding detailed specifications, application information, or any other general inquiries, please reach out to your local Barrett Technical Representative.

You can also call us directly at (800) 647-0100 or email us at info@barrettroofs.com